-

Research and Development

-

Mechanical Manufacturing

-

Electronics Manufacturing

-

Cable Assembly

-

System Integration & Testing

-

Kitting and Logistics

-

MRO & Technical Support

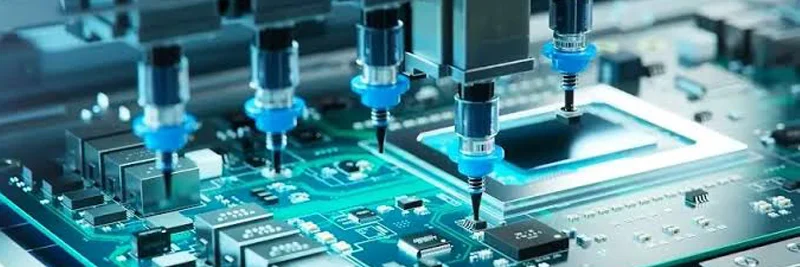

"Advanced PCB Assembly Solutions for Mission-Critical Applications"

At Questaero Systems Pvt. Ltd., we specialize in providing high-quality PCB Assembly services for the aerospace, defence, and medical industries. Our expertise in both Surface-Mount Technology (SMT) and Through-Hole Technology (THT) ensures that we can meet the specific requirements of your projects, whether for complex, high-density designs or more robust, industrial applications.

Our PCB Assembly Services:

SMT (Surface-Mount Technology)

We offer advanced SMT PCB Assembly services to assemble smaller, lighter components directly onto the surface of the PCB. This method is ideal for high-performance, compact designs used in aerospace, defence, and medical devices. Our capabilities in SMT allow us to handle small and fine-pitch components, ensuring precision and durability.

THT (Through-Hole Technology)

We also provide THT PCB Assembly for applications requiring larger components or more robust mechanical connections. This method is often used for mission-critical military and aerospace applications where durability and strength are key factors.

Mixed Technology Assembly

Combining both SMT and THT technologies, our mixed-technology assemblies offer flexibility for designing and producing complex PCBs. Whether you need high-density boards with small components or more rugged designs with robust connectors, we can provide customized solutions.

Prototype to Production

We handle everything from rapid prototyping to large-scale production runs, ensuring that your design is fully tested and validated before full production. Our quick-turn prototyping allows you to verify your design in real-time and make necessary adjustments before committing to mass production.

Key Features

High-Quality Standards

All our PCB assemblies are produced according to IPC-610 standards, ensuring exceptional quality and performance. We guarantee that each assembly meets stringent quality requirements and performs reliably in demanding environments.

Component Sourcing

We offer component sourcing to ensure that your PCBs are built with the best materials and components. Our global network of suppliers provides access to top-tier components, including resistors, capacitors, and ICs, that meet military, aerospace, and medical standards.

Testing & Quality Control

We perform extensive functional testing and in-circuit testing (ICT) to ensure that every PCB assembly meets its design specifications. We also conduct X-ray inspection for fine-pitch components and automated optical inspection (AOI) to detect potential defects early in the process.

Environmental Testing

To meet the demands of high-performance systems, we offer environmental testing for our PCBs, including thermal cycling, vibration testing, and electromagnetic interference (EMI) testing to ensure that your assemblies can withstand harsh operating conditions.

Why choose Us?

IPC Certification

Our PCB assembly process follows IPC-610 standards, ensuring that every assembly meets the highest quality standards. We have IPC-certified trainers on-site to ensure best practices are followed throughout the production process.

Experienced Team

Our team of highly trained engineers and technicians have extensive experience in PCB assembly for complex, mission-critical applications, ensuring that your designs are accurately realized with precision and reliability.

On-Time Delivery

We pride ourselves on meeting deadlines. Our efficient production process ensures that your PCB assemblies are delivered on time, every time.

Global Supply Chain

With access to a worldwide network of suppliers, we source components that meet industry-specific standards and regulatory requirements, ensuring that your PCB assemblies are built to the highest quality.

At Questaero Systems Pvt. Ltd., we are committed to delivering the highest-quality PCB assemblies for aerospace, defence, and medical industries. Our focus on precision engineering, rigorous testing, and on-time delivery ensures that your projects are executed flawlessly, even under the most demanding conditions.